Smart stainless steel assembly system (EMS) for frame structures in the food industry and in clean rooms

Stainless steel is the material standard for installations in clean rooms, for filling, packaging and conveying systems in the food industry and for all areas which are at risk from corrosion. As a specialist for niche products for these fields, we have now developed stainless steel connection elements which can be used in conjunction with special clamping technology to assemble and disassemble frame structures made from square or round tubing in the common size 40 quickly, reliably and without the need for specialist knowledge

EMS stainless steel assembly system product benefits

- Straightforward – assembly without the need for specialist knowledge, using just one tool

- Quick – considerable time savings thanks to assembly of pre-fabricated modules without reworking

- Flexible – easy to assemble/disassemble and reusable

- Stable – high-strength internal clamping mechanism

- Versatile – available for round tubing and square tubing

- Available – all components in stock and available for delivery

- With corrosion protection – all individual parts made of stainless steel

- Sustainable – suitable for mono-material recycling

EMS – the alternative to welded connections

Stable stainless steel railings or frames are typically manufactured by welding the respective stainless steel tubes. This is an extraordinarily labour-intensive process; after all, the tubes for the corner connections first have to be cut precisely to size, then welded and subsequently ground smooth. Afterwards, the welded seam also has to be pickled to prevent corrosion. And, in order to ensure that the frame also meets the optical requirements, polishing the pickled welded seams is indispensable. As well as taking time, all of these working steps also generate a lot of dirt, require well qualified specialist welders and suitable safety devices.

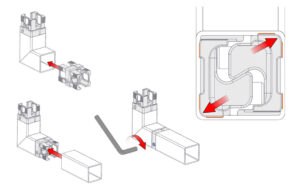

Assembling quickly, reliably and without specialist knowledge

Wouldn’t it be nice to be able to do without all this effort required for a welded connection? That’s exactly what the EMS connection elements make possible. Thanks to the new clamping connectors, none of the above tasks are necessary any more. The customer receives fully machined connection elements, including innovative clamping technology which can be combined with cut-to-length stainless steel tubes to form any kind of frame or railing.

Special clamping technology for stability

The special cast stainless steel clamping connectors, which are able to offset tolerances of up to two millimetres, are the key feature of the stainless steel assembly system. They are inserted into the tubes and the EMS connection elements, and firmly clamped in the tube by tightening a screw. This creates a secure connection which, at the same time, can be released at any time.

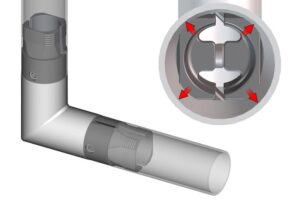

Connecting round pipes:

The connectors for round pipes consist of two half-shells that are braced in the pipe by tightening two Allen screws that press against each other. Ribs on the conically bevelled outer radius of the connectors are the first to press. Unlike conventional connectors, our EMS round connectors always have contact at four points in the pipe due to their special design. This prevents “tipping” and ensures a secure, centred all-round fit.

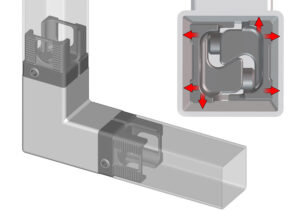

Connecting square tubes:

When connecting square tubes, the special design of the clamping connectors guarantees that uniform pressure is applied in all four directions. This ensures an integrated inclined plane through which the two half-shells interlock and thus stabilise. By spreading the half-shells diagonally with the help of two Allen screws, the geometry of the component creates six contact surfaces. This guarantees secure bracing.

A straight dimension of 23 millimetres for round tubes and twelve millimetres for square tubes was chosen for the distance between two tube sections. For design reasons, the distance between the round tubes is greater than that between the square tubes.

Five different basic elements

There are currently five different EMS elements available for delivery: corners, T connectors, cross connectors, 3-stream connectors and base elements with adjustable foot connection. In addition to the tapped hole – for screwing in the adjustable foot – the EMS base elements also have a second drilled hole which can be used to drain cleaning fluid. “Following the experiences with our ITAS system, we can certainly imagine expanding the EMS further too.”

Sustainable solution

Sustainability is just one of the numerous benefits of the EMS connectors: the connection elements can be combined with any kind of stainless steel round or square tubes in size 40. Frames assembled with them adapt to changes in framework conditions as they can easily be dismantled, transported without taking up much space, and re-assembled in another form. Given that they are made completely from stainless steel, the entire frame constructions are also suitable for mono-material recycling. Transporting welded steel frames is a complex process because a large volume and thus a lot of “air” has to be transported. Stainless steel frames for which our EMS is used, on the other hand, can be dismantled into compact segments. That makes transportation considerably more simple and reduces costs.

Ideal solution for clean rooms

Frames and working platforms for clean rooms used to be particularly challenging. Welded constructions do not fit in the clean room locks and welding in the clean room is of course unthinkable. That’s why RK Rose+Krieger modified the components of its system for industrial stairs and working platforms (ITAS) for its customers who manufacture in clean rooms.

With the EMS, it is possible to set up, modify and upgrade stainless steel frames in clean rooms with much less work required. All the stainless steel components – every connection element, every clamping element and every tube – can accordingly be cleaned properly, and packaged doubly airtight to be transported through the locks into the clean room.

Extensive stainless steel range

The EMS elements are not the only stainless steel products in the RK Rose+Krieger portfolio. Over the years, we have built up an entire portfolio of high-temperature and corrosion-resistant as well as wash-down stainless steel components, making us a specialist supplier for cleanrooms and food-related applications such as food packaging or conveying.

Thanks to the RK modular system, the products can be easily and quickly connected and combined with each other.